Ahh, the dreaded doors. I haven't met many folks who've said they enjoyed building the doors of their RV-10. Apparently the plans aren't the greatest, the scribe lines aren't very useful, and the parts themselves need a good amount of effort to make everything work properly. We do have the benefit, however, of following in the footsteps of many before us who documented what they did (or should have done) to make things easier during this process. Hopefully, that will help bigtime. So, here we go...

Wait... why aren't we continuing with the overhead console? Well, partially for a reason, and partially because why the heck not? The reason is that we want to do as much drilling and cutting as we can to the cabin cover before fabricating the overhead console, so we have a better understanding of what's going to go where and how all the parts fit together (hinges, strut, etc). Also, I wanted to take some more time to get even more experience with fiberglass, and I'll probably make one or two little things here and there as side-projects in order to become more familiar with the process. This isn't something a person can learn overnight!

In the meantime, I also built a crude "oven" (it's more of a "warmer" really) for our assortment of West System Epoxy. It turns out that epoxy is very temperature-sensitive and works best when just above normal room temperatures, like in the 80F-90F range. Especially as we head into the winter months here, the garage is going to be at the "bare-minimum" epoxy curing temperatures of 65-70 degrees, so the warmer the epoxy is, the better. I got the idea to make the oven originally from reading Rutan's Moldless Composite Sandwich Aircraft Construction manual, which is a highly recommended book geared towards builders of the many fabulous composite Rutan aircraft (Long-EZ, Cozy, etc), but is also very helpful for us rivet-bangers when it comes time to make fairings or custom bits for our RV's. Then, I saw one of these ovens for the first time in real life at my friend Chad's place the other day and thought, man, I gotta have one of these! So, I built one:

The EZ-Bake Oven (pun intended)

Oven from the outside, with other fiberglass-related goodies assorted all around

The oven is made from 100% genuine recycled Mikey J Scrap Material and is by no means the strongest or prettiest thing in the garage, but it came out just fine, works great, and I'm happy with it. It measures 24"L x 16"H x 16"D and is made of 1/4" plywood (thicker would have been better), some 2x2's at the corners, and 2x4's reinforcing the door. It was then lined with 1/2" insulation board, and all the cracks filled liberally with Great Stuff spray foam. The heater element is a standard 100W light bulb, and the thermostat is a Honeywell CT-410B line voltage thermostat. There's also a cheapie thermometer in there to ensure everything is working properly. The thermostat was an interesting piece, it is only rated to go up to 85 degrees F, but I was able to modify it to go higher. It turns out that all you have to do is pop the knob off the front of it, and the remaining part of the shaft will turn farther than the 85 degree stop, and will heat to at least 95 degrees or better (that's as high as I tried, but there was still more to go on the dial). Awesome! Now all of our epoxy-- except for the 205 "Fast" hardener-- is stored and incubating at around 80 degrees... we'll go higher if/as needed.

Now, on to the doors. We're going to start with the right door, and hopefully get to the point where the two halves are glued together, and then repeat with the left door. First thing to do is draw a couple lines around the window openings, and trim away the excess. Note: the plans aren't very clear about what exactly to trim, and the referenced figures show large crosshatched areas filled in around the door openings. Typically, this crosshatching in the plans means "cut this part away" although that is NOT the case here! Not very much trimming is needed at this time at all, just the middle of the window leaving a ~1-3/4" perimeter is fine. To draw the lines, I made a little "tab" out of scrap aluminum and drilled holes at the 3/4" mark and the 1-1/4" mark.

Measuring tab to aid in drawing spacing lines

3/4" and 1-1/4" lines drawn around the window opening. Another 1-3/4" line was drawn later and rough cuts were made along that line.

So far so good! Next we drilled a few index holes and sanded the inside surfaces (referred to as the "bag" side of the parts) where they will mate. The idea is to glue the door halves to each other while they are still oversize and can be laid over and clamped to the side of the fuselage. This way, the doors will match the contour of the fuselage exactly, and can then be trimmed to perfectly fit inside the door opening. Before long, we had the assembly clecoed to the side of the plane using the two index holes!

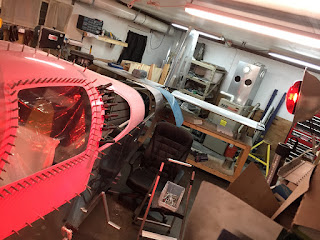

R Door laid over the cabin top for the first time, and a happy Sarah!

R Door from the inside

Neat! Next, we match-drilled a number of additional holes around the perimeter of the door. The holes along the bottom third of the door (that overlap the metal side skins) required use of a hole finder to match-drill into the holes previously left un-riveted in Section 29. I had always wondered why they had us leave those holes open... now I get it!

#40 Hole finder being used to match-drill the open holes in the side skins

Then, we departed from the plans and joined with several other folks who had a pretty smart idea to match-drill clecos just like this all the way around the rest of the door to hold it just perfect in place and shape. The holes will be easily filled later with some micro or flox, and if all goes well you'll never be able to tell we drilled a bunch of holes all around the door openings.

R Door match-drilled to fuselage

Close-up of upper aft side of door, formed perfectly to the cabin top

This is kind of cool! Now, everything has to come back apart and we have a few more steps to complete before epoxying the two halves together for good! I think I want to run a small conduit down the inside, as well as shoot some Great Stuff insulation into all the voids. We'll get to this hopefully this weekend!